At Impuls, we take pride in offering high-quality Polyurethane Adhesives that redefine precision and durability.

The use of polyurethane has a concrete effect on quality of life and the comfort of end users. Durable but safe at the same time, polyurethanes offer us comfort. Polyurethanes are essential for a comfortable modern life.

Polyurethane systems used in occupational safety boots with high hydrolysis, high abrasion resistance, antistatic and antibacterial features and it has two different product groups as single density and double density.

Polyurethane systems of 370 – 600 kg/m3 density, in various hardness values and used in shoe sole manufacturing.

Summer (hard) Sole

Winter (soft) Sole

Spring Sole

Wood Equivalent Sole

Polyurethane systems in various density and hardness values, used in slipper and sandal manufacturing with high flexibility resistance.

Polyurethane systems produced in two groups as polyether and polyesther and used to provide comfort inside the shoe.

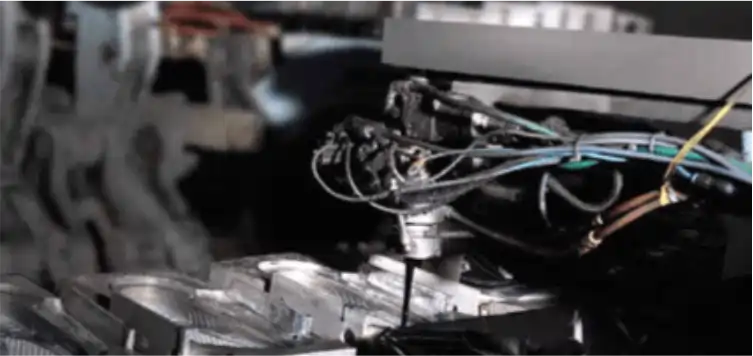

Polyurethane systems featuring high flexibility, low permanent deformation and incombustibility, that’s shaped by moulding and used in manufacturing of seating groups in automative and construction machines industry. It can be applied on vacuumed leather as well as being used with polyesther and aluminium moulds.

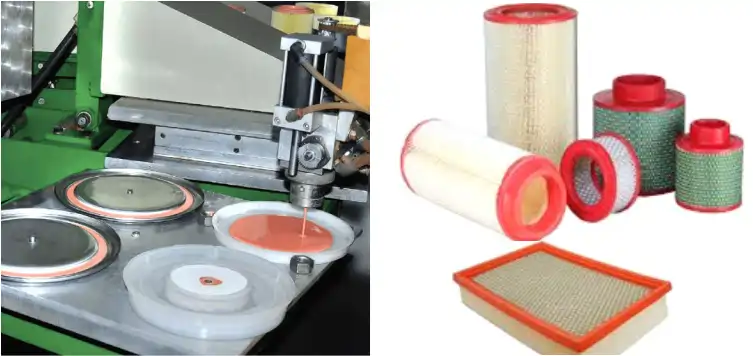

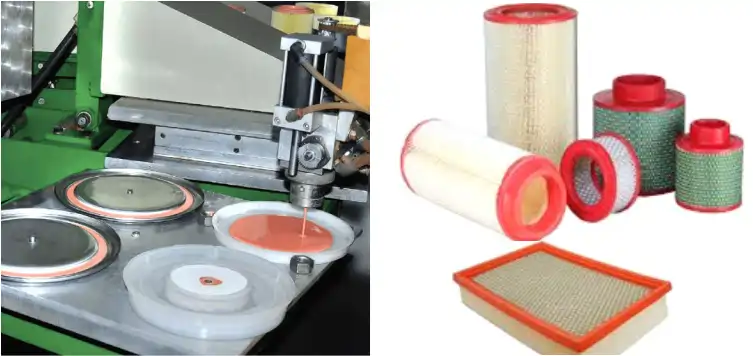

Water-based polyurethane systems used in filter manufacturing for vehicles such as automobiles, heavy vehicles, construction machines etc.

Polyurethane systems with high tearing strength and soft cell structure and used in automative, office furniture and medical industry with various density and hardness. Fields of use are office chair armrests, automobile steering wheels, door handles and similar applications.

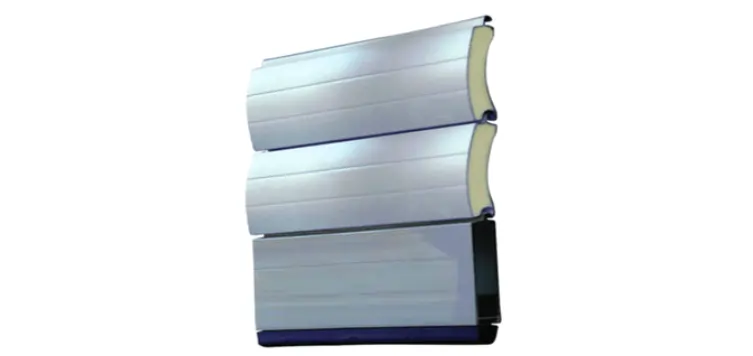

Systems with B1, B2 and B3 incombustibility according to DIN 4102 standard and that are in application densities of 35-44 kg/m to be applied between metal-metal, metal-membrane (PVC-TPU) used in roof and front coatings of structures such as factories, malls, cold-chamber depots, prefabricated etc. It consists of five components as polymyx, isocyanate, catalyst, solid and inflator agent.

Polyurethane systems consisting of polymyx and isocyanate, with 38-44 kg/m3 application density, used in cold-chamber panel manufacturing in cooling industry, that can be applied in discontinue presses and in B1, B2 and B3 incombustibility class according DIN 4102 standard.

Polyurethane systems used for heat, water and sound insulation purposes in roof, front, reverse ceiling and floors of buildings and in B1-B2 incombustibility class according to DIN 4102 standard.

Polyurethane systems used in insulation of pipes of sectional heating-cooling, underground and onground vapor transfers, geothermal energy, liquidified gasses (LNG, LPG etc.), fire lines, petroleum and transfer of all chemical flows.

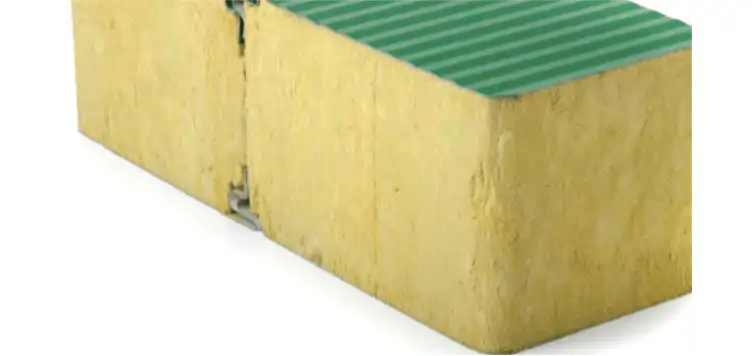

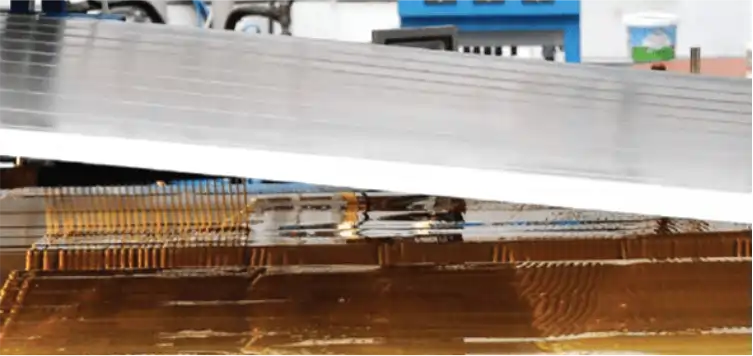

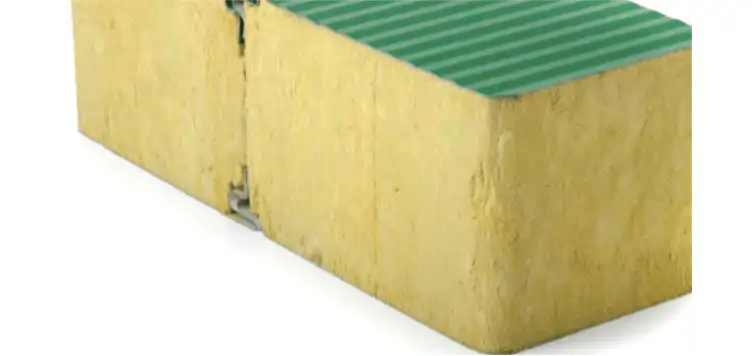

Polyurethane systems used in manufacturing of Eps-rockwool filled panels, that can bond surfaces such as dyed-galvanized sheet, alluminium, membrane etc., can be applied with dripping or spraying machines and having B2 and B3 incombustibility value according to DIN 4102 standard.

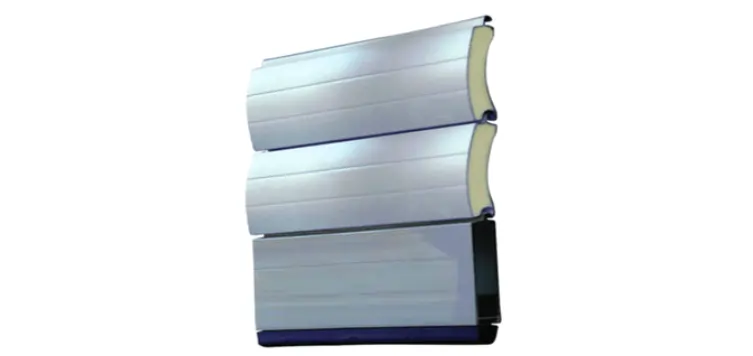

Polyurethane systems used to provide heat insulation and strengthen the durability in blinds and shutter systems of houses, offices and parking areas.

Dual component polyurethane coating product used in coatings of pools, bridges, exteriors, parking areas and marine vehicles like yachts-boats because of its’ outstanding features like non-solvent chemical, mechanical and hydrolysis resistance. Preferred for tis’ fast curing and strong bonding to surface.

Polyurethane systems used for decoration and heat insulation purposes.

A single component, polyether-based binder. Used mainly to bind granule rubber particles for coating kids’ playground, sport fields, walking trails. Can be applied with moulding and casting method.

A single component polyurethane adhesive containing no solvent and cured with moisture. Suitable for concrete, brick, metal, laminate, alluminium and plastics in manufacturing and repairing of furnitures, boats, wooden door and windows, acoustic panels, stairs and fitted kitchen. Becomes water and sea-water resistant 24 hours after the application.

Polyurethane systems used for heat insulation in water heating systems. As for solar collectors, they’re used to keep the temperature fixed in solar energies, heating systems and boilers.

Polyurethane systems that consist of polymyx and isocyanate and used for heat insulation in refrigerators. It’s suitable to use CP 70 or CP 95 as inflator agents during production process. It has a thermal conductivity coefficient value between 0.021-0.022 W/Mk. Products such as commercial type deep freezers, mini bars and beverage cabinets etc. on the other hand are polyurethane systems that consist of polymyx, insulation purpose isocyanate and inflator agents. Next generation, eco-friendly gasses are used as inflator agents.

With the help of their high fluidity feature during application foam systems can be used with moulds in every shape. It’s suitable to use with supportive materials such as plastic, metal and wood. Because it can be worked on with wide ratios of isocyanat, the hardness of the final product moulded can be adjusted to desired measure.

Polyurethane systems that provides decorative using advantage and used generally in furniture and wood industry.

Polyurethane systems used in occupational safety boots with high hydrolysis, high abrasion resistance, antistatic and antibacterial features and it has two different product groups as single density and double density.

Polyurethane systems of 370 – 600 kg/m3 density, in various hardness values and used in shoe sole manufacturing.

Summer (hard) Sole

Winter (soft) Sole

Spring Sole

Wood Equivalent Sole

Polyurethane systems in various density and hardness values, used in slipper and sandal manufacturing with high flexibility resistance.

Polyurethane systems produced in two groups as polyether and polyesther and used to provide comfort inside the shoe.

Polyurethane systems featuring high flexibility, low permanent deformation and incombustibility, that’s shaped by moulding and used in manufacturing of seating groups in automative and construction machines industry. It can be applied on vacuumed leather as well as being used with polyesther and aluminium moulds.

Water-based polyurethane systems used in filter manufacturing for vehicles such as automobiles, heavy vehicles, construction machines etc.

Polyurethane systems with high tearing strength and soft cell structure and used in automative, office furniture and medical industry with various density and hardness. Fields of use are office chair armrests, automobile steering wheels, door handles and similar applications.

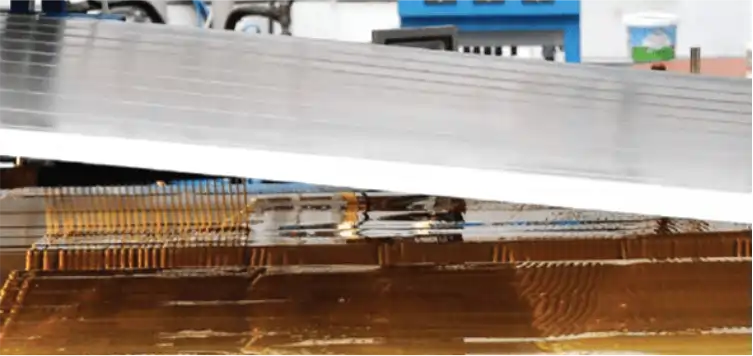

Systems with B1, B2 and B3 incombustibility according to DIN 4102 standard and that are in application densities of 35-44 kg/m to be applied between metal-metal, metal-membrane (PVC-TPU) used in roof and front coatings of structures such as factories, malls, cold-chamber depots, prefabricated etc. It consists of five components as polymyx, isocyanate, catalyst, solid and inflator agent.

Polyurethane systems consisting of polymyx and isocyanate, with 38-44 kg/m3 application density, used in cold-chamber panel manufacturing in cooling industry, that can be applied in discontinue presses and in B1, B2 and B3 incombustibility class according DIN 4102 standard.

Polyurethane systems used for heat, water and sound insulation purposes in roof, front, reverse ceiling and floors of buildings and in B1-B2 incombustibility class according to DIN 4102 standard.

Polyurethane systems used in insulation of pipes of sectional heating-cooling, underground and onground vapor transfers, geothermal energy, liquidified gasses (LNG, LPG etc.), fire lines, petroleum and transfer of all chemical flows.

Polyurethane systems used in manufacturing of Eps-rockwool filled panels, that can bond surfaces such as dyed-galvanized sheet, alluminium, membrane etc., can be applied with dripping or spraying machines and having B2 and B3 incombustibility value according to DIN 4102 standard.

Polyurethane systems used to provide heat insulation and strengthen the durability in blinds and shutter systems of houses, offices and parking areas.

Dual component polyurethane coating product used in coatings of pools, bridges, exteriors, parking areas and marine vehicles like yachts-boats because of its’ outstanding features like non-solvent chemical, mechanical and hydrolysis resistance. Preferred for tis’ fast curing and strong bonding to surface.

Polyurethane systems used for decoration and heat insulation purposes.

A single component, polyether-based binder. Used mainly to bind granule rubber particles for coating kids’ playground, sport fields, walking trails. Can be applied with moulding and casting method.

A single component polyurethane adhesive containing no solvent and cured with moisture. Suitable for concrete, brick, metal, laminate, alluminium and plastics in manufacturing and repairing of furnitures, boats, wooden door and windows, acoustic panels, stairs and fitted kitchen. Becomes water and sea-water resistant 24 hours after the application.

Polyurethane systems used for heat insulation in water heating systems. As for solar collectors, they’re used to keep the temperature fixed in solar energies, heating systems and boilers.

Polyurethane systems that consist of polymyx and isocyanate and used for heat insulation in refrigerators. It’s suitable to use CP 70 or CP 95 as inflator agents during production process. It has a thermal conductivity coefficient value between 0.021-0.022 W/Mk. Products such as commercial type deep freezers, mini bars and beverage cabinets etc. on the other hand are polyurethane systems that consist of polymyx, insulation purpose isocyanate and inflator agents. Next generation, eco-friendly gasses are used as inflator agents.

With the help of their high fluidity feature during application foam systems can be used with moulds in every shape. It’s suitable to use with supportive materials such as plastic, metal and wood. Because it can be worked on with wide ratios of isocyanat, the hardness of the final product moulded can be adjusted to desired measure.

Polyurethane systems that provides decorative using advantage and used generally in furniture and wood industry.